Yard Management in SAP

Efficient control of factory traffic, gate and ramp handling with

the yard management of SERKEM.

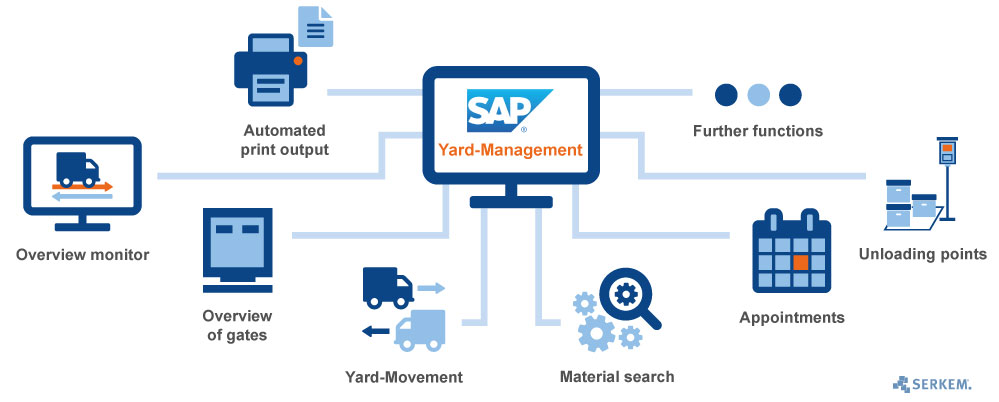

The SERKEM solution in detail

The yard management system is used for monitoring and controlling vehicle movements. It enables the coordinated management of ramp allocation and gate processing.

By implementing the yard management system, you can optimize the timing and locations for the loading and unloading of vehicles. This helps to avoid waiting times at ramps or gates and increases processing speed. Various operations are automatically recorded in the system, giving you a real-time overview of all vehicles currently on the premises.

Companies with large premises, heavy traffic, multiple loading points, or several locations particularly benefit from using the yard management system. When combined with our solutions for swap body management and load carrier/container management, visibility and efficiency can be further enhanced.

At a glance

The yard management in SAP makes a transparent, efficient and reliable control of factory traffic possible.

- Efficient processing of incoming and outgoing truck transports through entry and departure control of truck traffic

- Gapless documentation of the whole factory traffic in SAP

- Monitoring of all trucks which are located in the yard

- Increase of handling speed, avoiding of wait times

- Monitoring of all transports for the chosen location in dependence of different selection criteria

- Control and reporting functions as well as statistics, e.g. provisional appointment, route planning, yard retention time, time differences between entry and end of loading

- Printing and pre-shipment of documents like yard control receipt, weigh protocol, loading list etc.

- Scale integration with traffic light display of overloading

- Development completely in SAP

- Determination of entry/departure weight over electronic scale with monitoring at truck overload

- Provisional appointment: already known route dates for route planning can be registered in advance and used for control and reporting purposes

- Load list can be sent in advance per mail to the forwarder

- Data collection for vehicles with entry of motor vehicle number, weight determination and set status

- Assignment of loading track and creation of transportation orders: monitoring of loading track at the beeper

- Documents like yard control receipt, weigh protocol, loading list, etc can be printed

- Calculation of different time differences with award of the reason at too big differences

- Preset of values for registration from proposal table

- Extensive statistics (yard residence time etc)

- Registration oft rucks and transportation goods at entry and departure

- Monitoring of all trucks which are located in the yard

- Entry of route and beeper number according to trucks

- Extension of the list with gate number

- Beeper integration through SAP Phone

- Selection possibilities over entries and departures within a period of time

- Comparison with announced transports/orders in the SAP ERP system

- Optional acknowledgment over barcode solution, manual confirmation or coupled to the handling in shipment

Extract from our References

Holsten (Carlsberg A/S Gruppe)

- Brewery

- Turnover: 8.8 Mrd. €

- Employee: 47.000 (2015)

ZF Friedrichshafen AG:

- Automotive industry

- Turnover: 16,8 Mrd. €

- Employee: 72.643